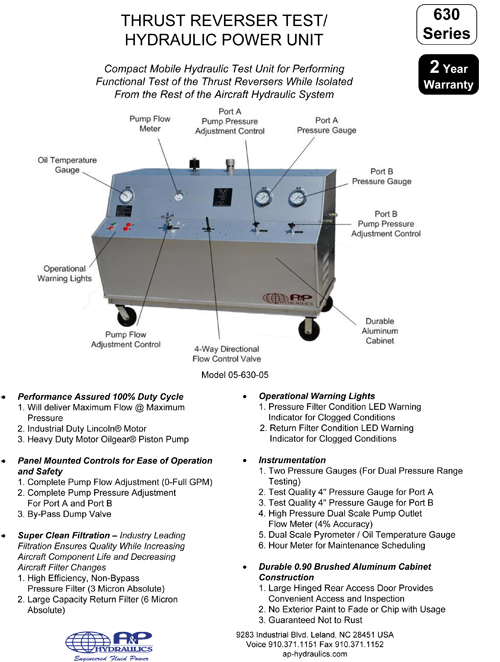

Series 630 Thrust Reverser Test compact mobile hydraulic test unit.

Series 630, Thrust Reverser Test

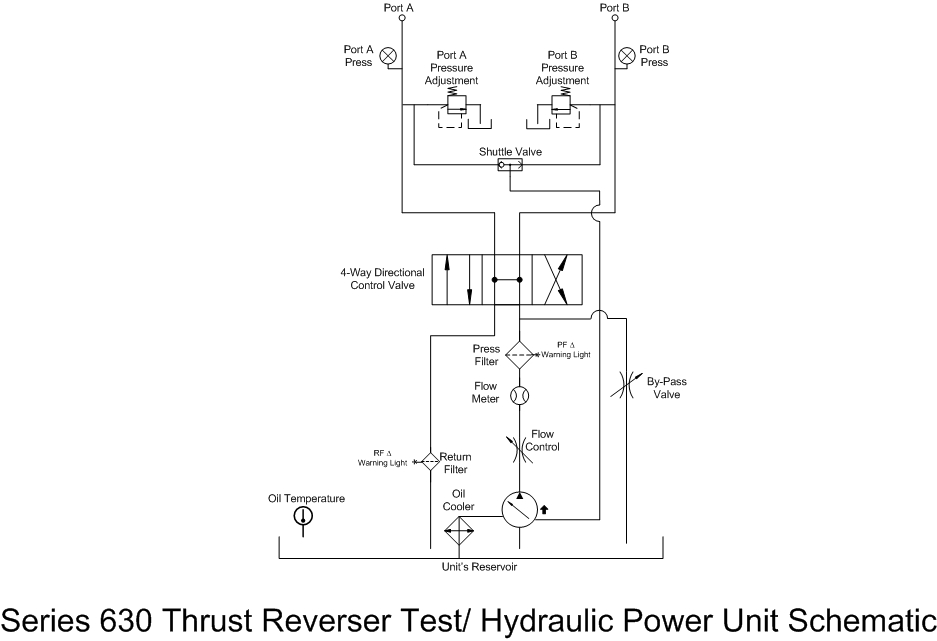

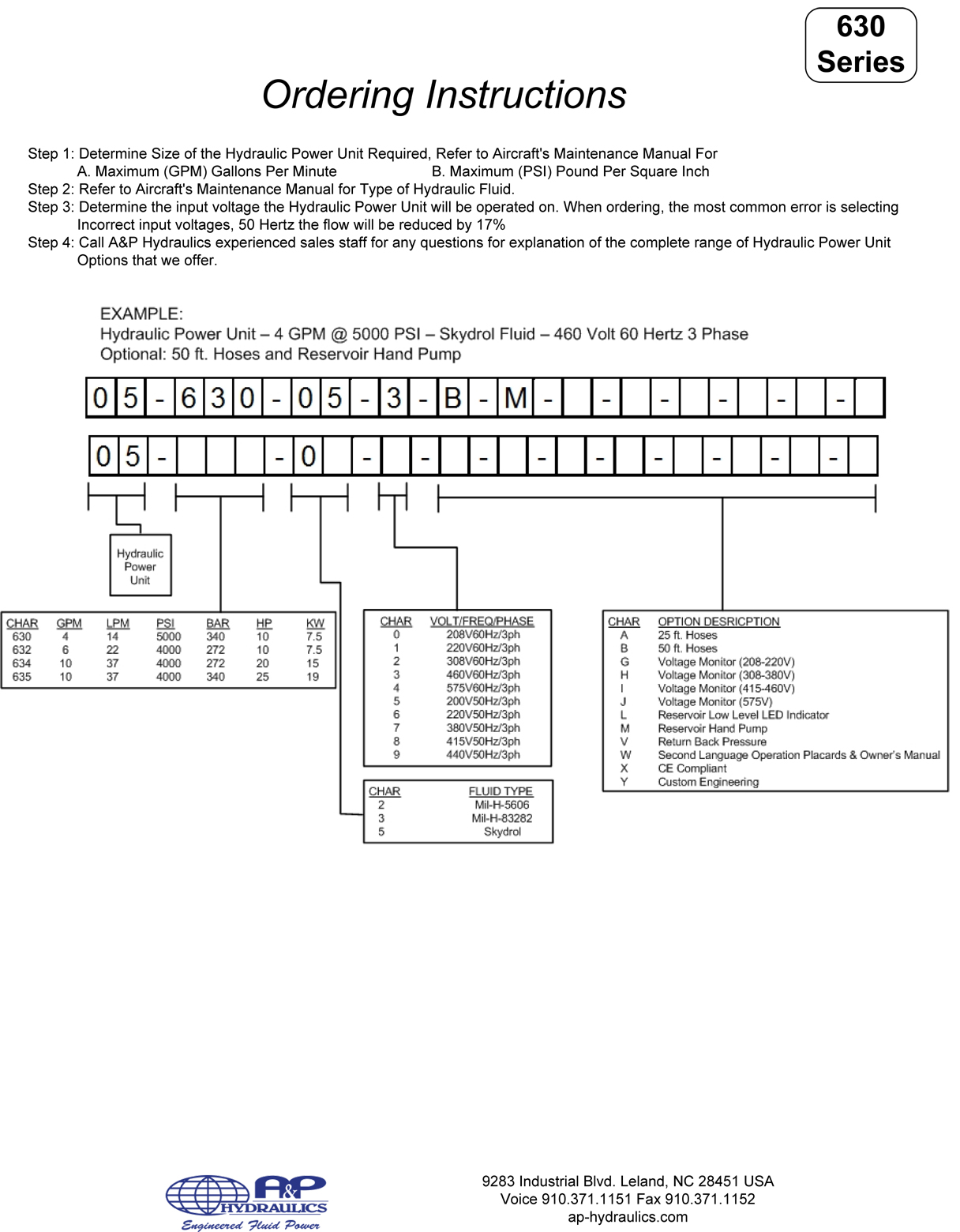

The Series 630 thrust reverser test (4 - 10 GPM) is a compact mobile hydraulic test unit for performing functional test of the thrust reversers while isolated from the rest of the aircraft hydraulic system.

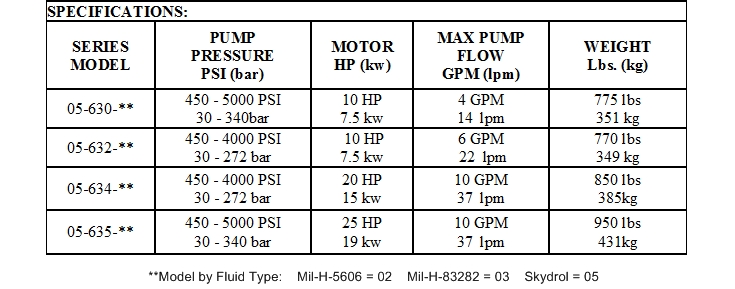

Standard Features & Specifications

Thrust Reverser Test

Thrust Reverser Test (model #05-630-05)

The 630 thrust reverser test is a compact mobile hydraulic test unit for performing functional test of the thrust reversers while isolated from the rest of the aircraft hydraulic system.

- Performance Assured 100% Duty Cycle

- Will deliver Maximum Flow @ Maximum Pressure

- Industrial Duty Lincoln� Motor

- Heavy Duty Motor oil gear� piston pump

- Panel Mounted Controls for Ease of

Operation and Safety

- Complete Pump Flow Adjustment (0-Full GPM)

- Complete Independent Pressure Adjustment for Port A and Port B

- Manual 4-way Directional Flow Control Valve

- By-pass Dump Valve

- Super Clean Filtration -

Industry Leading

Filtration

Ensures Quality While Increasing Aircraft

Component Life and Decreasing Aircraft Filter

Changes- High Efficiency,

Non-Bypass Pressure

Filter (1 Micron Absolute) - Large Capacity Return Filter (3 Micron Absolute)

- High Efficiency,

Non-Bypass Pressure

- Operational Warning Lights

- Pressure Filter Condition LED

Warning

Indicator Clogged Conditions - Return Filter Condition LED

Warning

Indicator Clogged Conditions

- Pressure Filter Condition LED

Warning

- Instrumentation

- Two Pressure Gauges (for dual pressure range testing)

- Test Quality 4" Pressure Gauge for Port A

- Test Quality 4" Pressure Gauge for Port B

- Dual Scale Pump Output Flow Meter (4% accuracy)

- Dual Scale Pyrometer/Oil Temperature Gauge

- Hour Meter for Maintenance

Scheduling

- Durable 0.90 Brushed Aluminum

Cabinet Construction

- Large Hinged Rear Access Door

Provides Convenient

Access and Inspection - No Exterior Paint to Fade or Chip with Usage

- Guaranteed Not to Rust

- Large Hinged Rear Access Door

Provides Convenient

Standard Features:

- Current Pressure Gauge and

Flow Meter

Certificate of Calibration - High Efficiency Aluminum Oil

Cooler with

3 Phase Fan - Stainless Steel Reservoir (20 gallons)

- Port A and Port B Standard #8 Pressure Hoses, 15 ft (4.5 m) Long

- Standard 50 ft. (15.2 m) Electrical Input Cable

- Large Hinged Rear Access Door

Provides

Convenient Access and Inspection - Easy Access

Exterior Fluid Sampling

Valve to Meet Quality Parameters

- All Welded .090 Aluminum Construction

- Heavy Duty Welded Frame

- All Electrical Components Installed in Liquid Tight Enclosure (NEMA 4, 12)

- Guaranteed No Leaks, Aluminum Pan Completely Covers Bottom of Unit

- Durable Aluminum, Laser Engraved Placards

- Panel Mounted Operational Instructions

- Easy Maneuvering Ensured

with Two Fixed and Two Swivel Castors with Stability Provided by the

Heavy Duty Floor Lock

Dimensions: Length 69 in (175 cm), Width 36 in (91 cm), Height 40 in (102 cm)