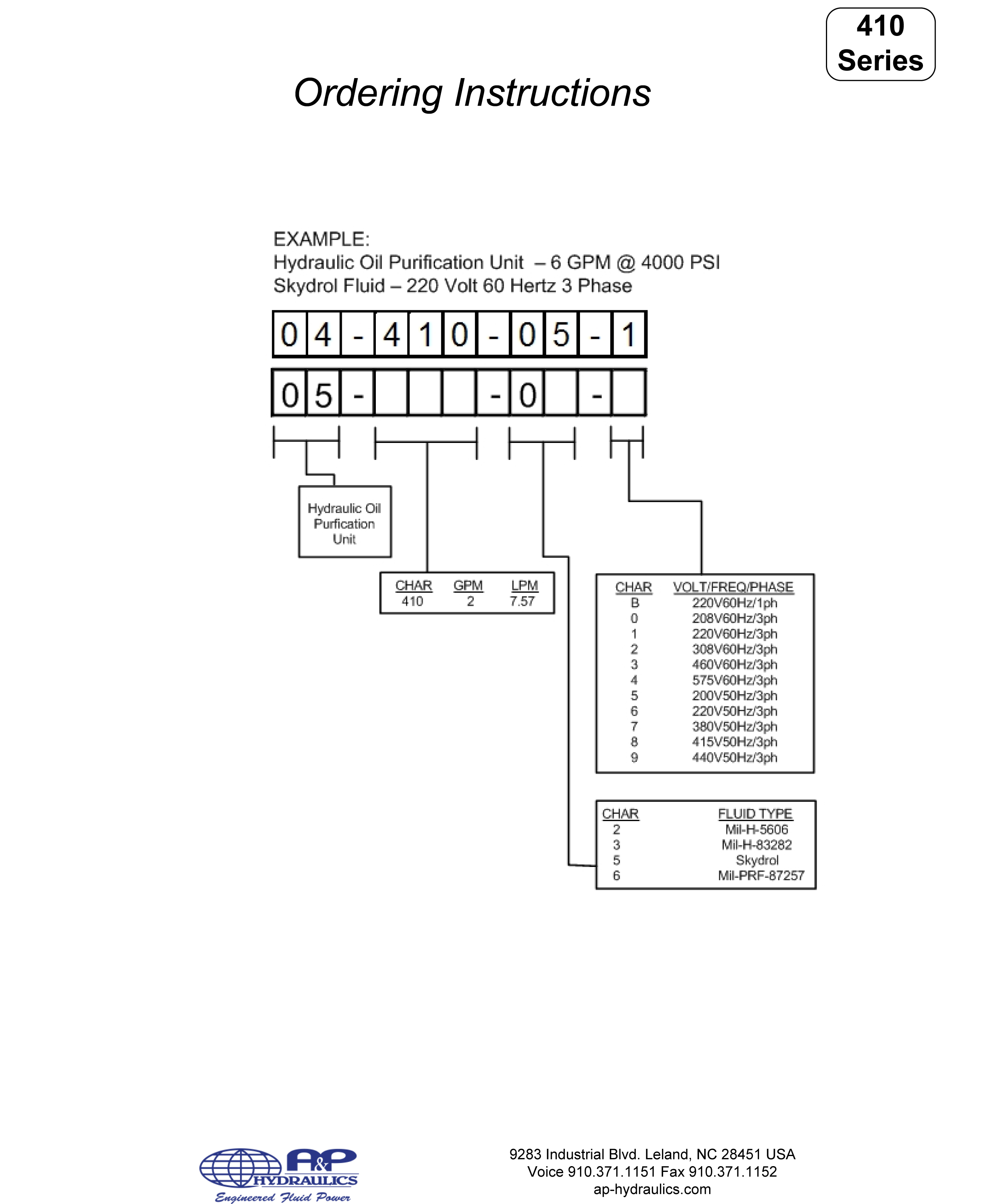

Series 410 Fluid Servicing Unit hydraulic oil purification unit

Series 410, Hydraulic Oil Purification Unit

The Series 410 Fluid Servicing, hydraulic oil purification unit provides quick payback on investment by significantly reducing fluid waste disposal, liabilities and new fluid replacement frequency.

Standard Features & Specifications

Hydraulic Oil Purification Unit

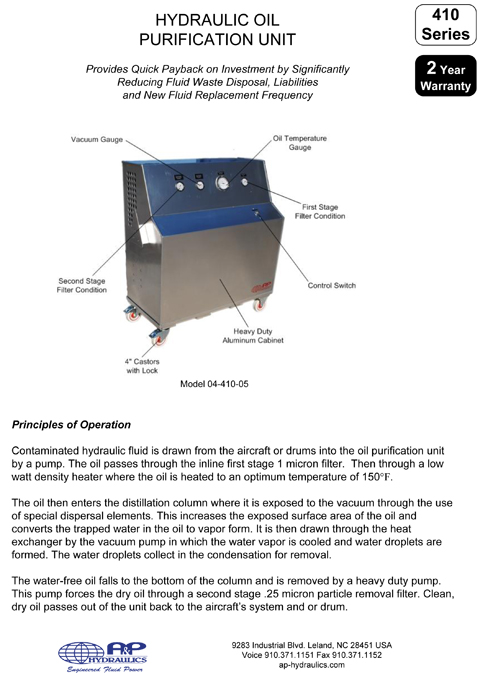

Hydraulic Oil Purification Unit (model #04-410-05) Principles of Operation

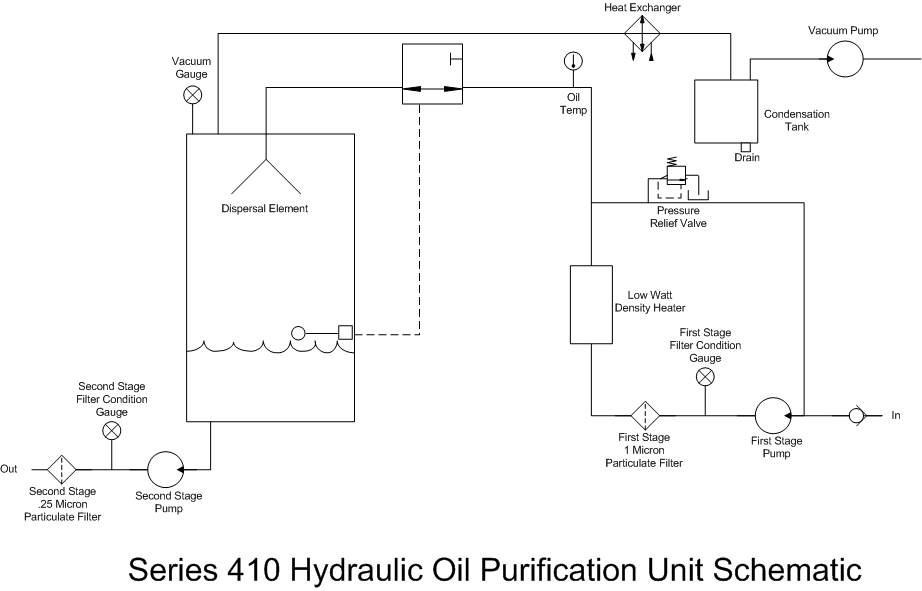

Contaminated hydraulic fluid is drawn from the aircraft or drums into the oil purification unit by a pump. The oil passes through the inline first stage 1 micron filter. Then through a low watt density heater where the oil is heated to an optimum temperature of 150F.

The oil then enters the distillation column where it is exposed to the vacuum through the use of special dispersal elements. This increases the exposed surface area of the oil and converts the trapped water in the oil to vapor form. It is then drawn through the heat exchanger by the vacuum pump in which the water vapor is cooled and water droplets are formed. The water droplets collect in the condensation for removal.

The water-free oil falls to the bottom of the column and is removed by a heavy duty pump. This pump forces the dry oil through a second stage .25 micron particle removal filter. Clean, dry oil passes out of the unit back to the aircraft's system and or drum.

- Two Stage Particulate

Filter

A. First Stage (1 Micron)

B. Second Stage (.25 Micron) - Removes

A. Free Dissolved Water

B. Free Dissolved Air

C. Chlorinated Solvent

D. Particulates down to 16/14/11 level - Will Not Remove Additives of Hydraulic Fluid

- Suction Pump for Removal of Fluid from Drums or Aircraft System

- Fully Enclosed, Aluminum Cabinet

- 4" Casters with Wheel Locks

- Panel Mounted Gauges and Controls for Easy Operation

- Input Electrical Cord (25 ft.)

- External Hoses

A. Suction Hose (25 ft. long, #8 JIC)

B. Supply Hose (25 ft. long, #8 JIC) - Durable Laser Engraved Placards

- Available Electrical Input

1. 208 VAC 3 Phase

2. 220 VAC 3 Phase

3. 460 VAC 3 Phase

4. 380 VAC 3 Phase

5. 575 VAC 3 Phase