Series 610 Hydraulic Power Unit designed for corporate/occasional use operations.

Series 610, Hydraulic Power Unit

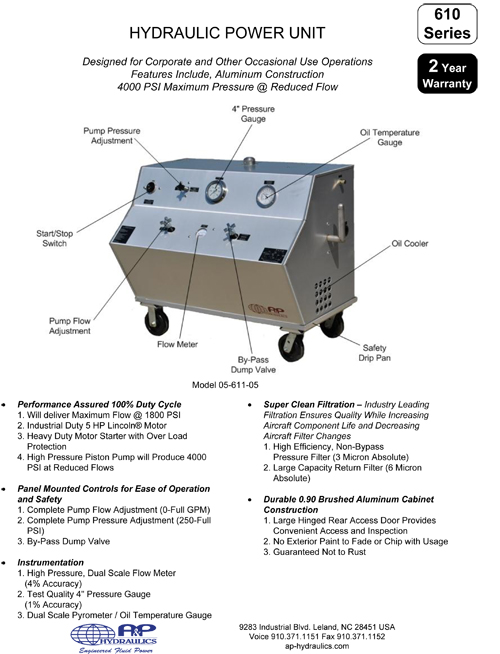

The Series 610 hdyraulic power unit (6 GPM) is designed for corporate and other occasional use operations. Features include aluminum construction, 4000 PSI maximum pressure at reduced flow.

For Aircrafts: Bell 212/UH-1H, Bell 206B-JR2, Bell 206L-3, Bell 206B3, Bell Jetranger, Bell 206LT Light Utility, Bell 222, Bell 230, Bell 430, Bell 427, CASA CN-235, CASA CN-295, Cessna 500 Citation I, Cessna 501 Citation I/SP, Cessna 550 Citation II, Cessna 550 Citation II, Cessna 551 Citation II/SP, Cessna S550 Citation S/II, Cessna 560 Citation V, Cessna Citation Bravo, Cessna Citation Ultra, Cessna 525 CitationJet, Cessna 525 CitationJet CJ1, Cessna 525A CitationJet CJ2, Cessna 525B CitationJet CJ 3, Raytheon BeechJet Diamond .

Standard Features & Specifications

Heavy Duty Hydraulic Power Unit

- Performance Assured 100% Duty Cycle

- Will deliver Maximum Flow @ 1800 PSI

- Industrial Duty 5 HP Lincoln� Motor

- Heavy Duty Motor Starter with Over Load Protection

- High Pressure Piston Pump will Produce

4000 PSI at Reduced Flows

- Panel Mounted Controls for Ease of

Operation and Safety

- Complete Pump Flow Adjustment (0-Full GPM)

- Complete Pump Pressure Adjustment (250-Full PSI)

- By-Pass Dump Valve

- Instrumentation

- High Pressure, Dual Scale Flow Meter (4% accuracy)

- Test Quality 4" Pressure Gauge (1% accuracy)

- Dual Scale Pyrometer / Oil Temperature Gauge

- Super Clean Filtration -

Industry Leading

Filtration

Ensures Quality While Increasing Aircraft

Component Life and Decreasing Aircraft Filter

Changes- High Efficiency,

Non-Bypass Pressure

Filter (1 Micron Absolute) - Large Capacity Return Filter (3 Micron

Absolute)

- High Efficiency,

Non-Bypass Pressure

- Durable 0.90 Brushed Aluminum

Cabinet Construction

- Large Hinged Rear Access Door

Provides Convenient

Access and Inspection - No Exterior Paint to Fade or Chip with Usage

- Guaranteed Not to Rust

- Large Hinged Rear Access Door

Provides Convenient

Standard Features:

- Will Deliver Maximum Flow @ 1800 PSI

- Higher Pressure @ Reduced Flows (4000 PSI @ 1.5 GPM)

- Durable Pressure Compensated Piston Pump

- Heavy Duty 3 Phase Motor

*Single Phase Motor Available - All Welded 0.90 Aluminum Construction

- Pump Case Drain Oil Cooler

- Stainless Steel Reservoir (10 Gallons)

- Reservoir Selector Valves

(to use either aircraft's or unit's reservoir) - Standard #8 Pressure Hoses

and #12 Return

Hoses, 15 ft. (4.5 m) Long - Current Pressure Gauge and

Flow Meter

Certificate of Calibration

- Standard 50 t. (15.2 m) Electrical Input Cable

- Guaranteed No Leaks, Aluminum Pan Completely Covers Bottom of Unit

- Durable Laser Engraved , Aluminum Placards

- Panel Mounted Operational Instructions

- Easy Access Exterior Fluid

Sampling Valve

Meet Quality Parameters - Easy Maneuvering Ensured

with Two Fixed and

Two Swivel Castors and Stability Provided by the

Heavy Duty Floor Lock - Heavy Duty Bracket for

Hose and Electrical Input

Cord Storage - Large Hinged Rear Access Door Provides Convenient Access and Inspection

Dimensions: Length 42 in (107 cm), Width 28 in (71 cm), Height 32 in (81 cm)