Series 510 Hydraulic Power Unit independent dual system, diesel powered HPU.

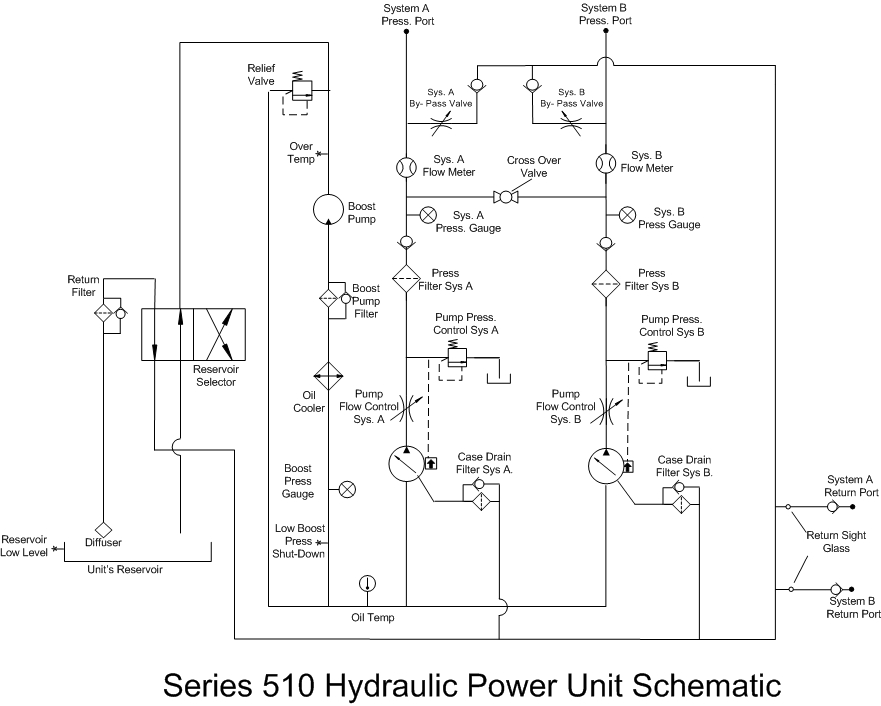

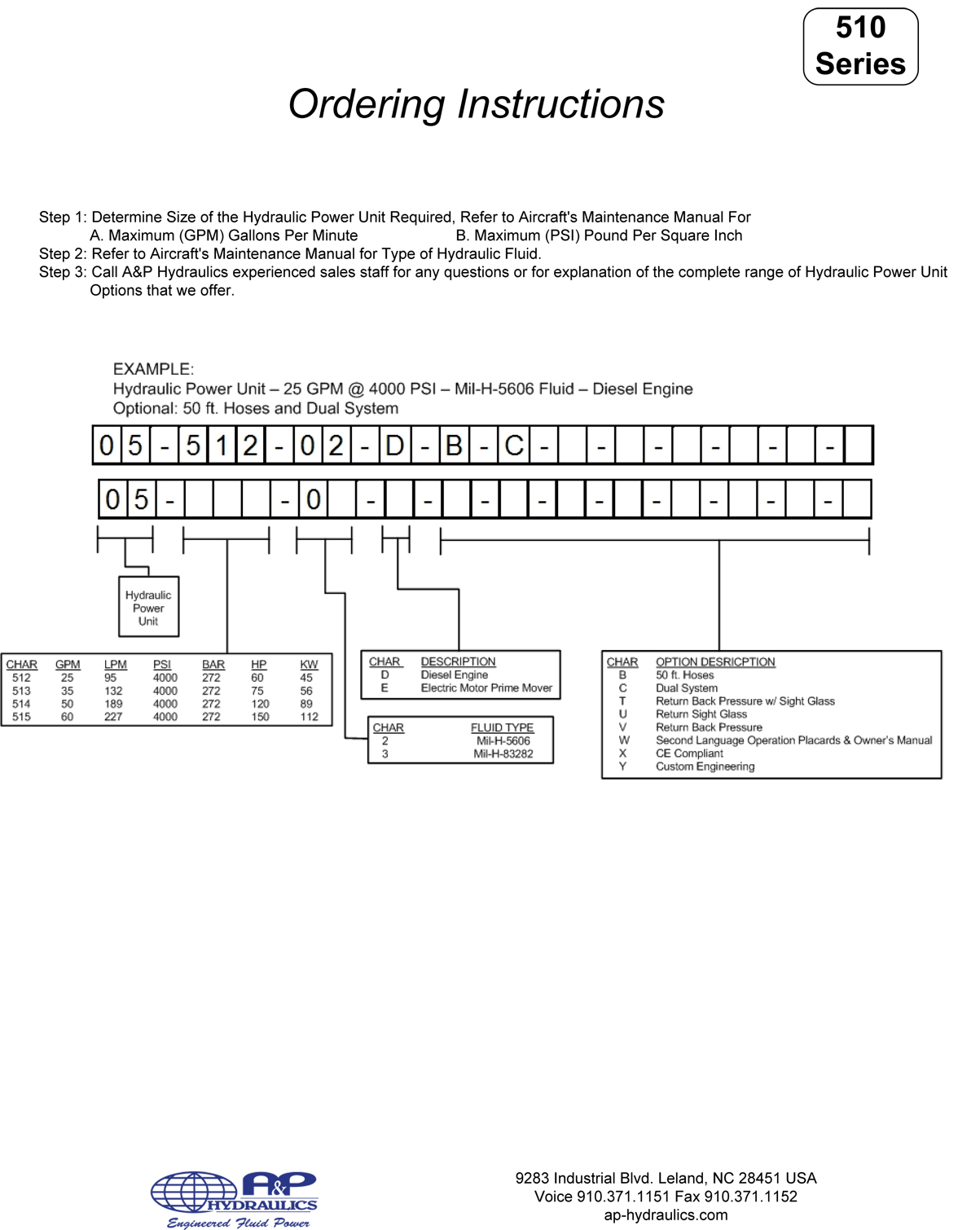

Series 510, Hydraulic Power Unit

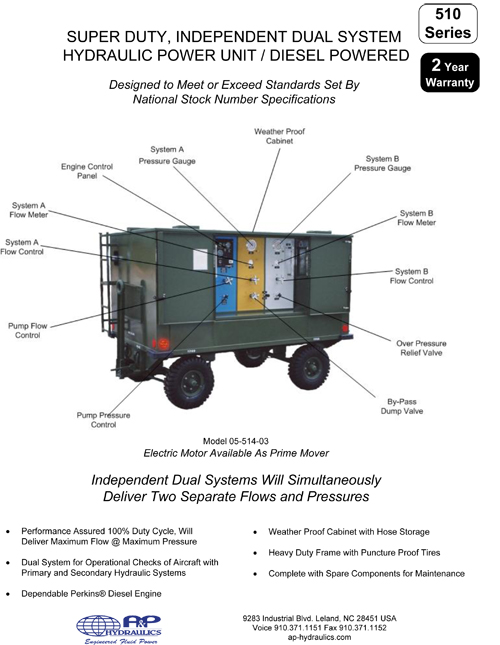

The Series 510 hdyraulic power unit (25 - 60 GPM) is designed to meet or exceed standards set by National Stock Number Specifications. Electric motor available as prime mover. The independent dual systems will simultaneously deliver two separate flows and pressures.

Dual system for operational checks of aircraft with primary and secondary hydraulic systems. Weather proof cabinet with hose storage, heavy duty frame with puncture proof tires. Complete with spare components for maintenance.

Standard Features & Specifications

Super Duty Dual System Hydraulic Power Unit

- Performance Assured 100% Duty Cycle,

Will Deliver Maximum Flow @ Maximum Pressure - Dual System for Operational Checks of

Aircraft with

Primary and Secondary Hydraulic Systems - Dependable Perkins� Diesel Engine

- Weather Proof Cabinet with Hose Storage

- Heavy Duty Frame with Puncture Proof Tires

- Complete with Spare Components for Maintenance

- Independent Dual Systems-

- System A and System B May Be

Used Independently

or Combined Together for Maximum Flows - System A and System B Will

Deliver Different Pressures

and Flows Simultaneously - Cross Over Valve Incorporated

for Combined Flows

for Maximum Performance - Independent Dual System Includes:

- Independent Dual Pumps

- Independent Dual Flow Meters

- Independent Dual Pressure Gauges

- Independent Dual Flow and

Pressure

Control Valves - Independent Dual By-Pass Valves

- Dual Pressure Hoses (35 ft. Long)

- Dual Return Hoses (35 ft. Long)

- Instrumentation

- Dual Variable Area Flow Meters (4% Accuracy)

- Dual Test Quality Pressure Gauges (1% Accuracy)

- Dual Scale Pyrometer / Oil

Temperature Gauge

(2% Accuracy) - Test Quality Boost Pump Pressure Gauge

Leading Particulars

|

Item |

Specifications |

|

Purpose |

To test independent hydraulic systems of aircraft. |

|

Functions |

a. Boost pump for close loop circuit. b. Open loop configuration for filling and draining of A/C reservoir. c. Dual system with dual in and outlets with shut off valves. |

|

Performance |

a. Maximum pressure at maximum flow: 300 - 3000 PSI, 4000 PSI b. Flow Range: refer to model number |

|

Engine |

Perkins� Diesel Engine |

|

Hydraulic System |

a. Axial piston pump variable stroke with proportional control of flow and pressure b. Fluid Sample Port c. Pressure filter 3 micron absolute, low pressure filter 10 micron absolute with electric clogged conditions indicator d. Stainless steel reservoir capacity 150% of maximum pump output (refer to model number) e. Pressure and return hoses 35 ft. long f. High volume hand pump with filter and pressure gauge for servicing aircraft's reservoir |

|

Switches/Gauges/Indicators |

a. Analog pressure gauge 0-4000 PSI in pressure line and 0-200 PSI in return line (1% Accuracy) b. Analog read out for actual flow c. Flow setting by flow control valve d. Pressure setting by pressure relief valve e. Temperature shut down switch f. Emergency shut-down button g. Low pressure filter clogged conditions indicator h. Switch for low and high level and return pressure gauge |

|

Control Panel |

a. Contains all control gauges and indicators for hydraulic system b. Accessible through hinged panel in a dust and water proof housing c. Illuminated to enable easy operation at night d. Graphic lay out for ease of operation e. Protective cover for control panel |

|

Safety System |

HTS have all required safeties pertaining to electrical, Hydraulic and emergency system. |

|

Structure |

a. Strong and heavy duty chassis. b. Heavy duty frame with dip tray. Hydraulic and Electrical components completely isolated from each other. c. Canopy out of steel, spray painted. d. Maximum towing speed 16 Km/hour, parking brake on front wheel by tow in upright position. e. Tie down / lifting points. Fork-lift pick-up points. |

|

Noise Level |

a. Less than 75 dbA at two meter distance. |

|

Accessories |

a. Bottle samplers for laboratory check of contamination to be provided with each HTS. b. All models incorporate in Line Sensor for connection with Hydraulic contamination. c. One set of hydraulic pressure and return lines, 35 ft. long d. One 45 Watt swiveling spot light with each HTS. e. One CO2fire extinguisher mounted on outside of unit. f. One tool kit for routine scheduled/unscheduled maintenance with each unit. |

|

Publications |

a. 2 Sets of Operation Manual b. Engine maintenance and IPC manual for complete overhauling of engine |

|

Training |

One week training, depot level maintenance on troubleshooting, rectification, and maintenance |

|

Spare Parts |

a. Hydraulic pressure filter 6 sets and o-rings b. Boost pump filter 6 sets spin on elements c. Return filter 6 sets spin on elements d. Reservoir service pump filter 2 sets spin on elements e. Diesel engine fuel filter 4 sets f. Diesel engine air filter 2 sets g. Pump gasket kit 1 set h. O-ring set for all manual valves 1 set i. Spare puncture proof tire 1 each j. Availability of parts 20 years |

|

Warranty |

a. Frame and running gear 5 years b. Diesel engine 3 years c. Pumps 2 years d. Complete hydraulic system 2 years |

Dimensions: Length 32 in (81 cm), Width 20 in (51 cm), Height 38 in (97 cm)